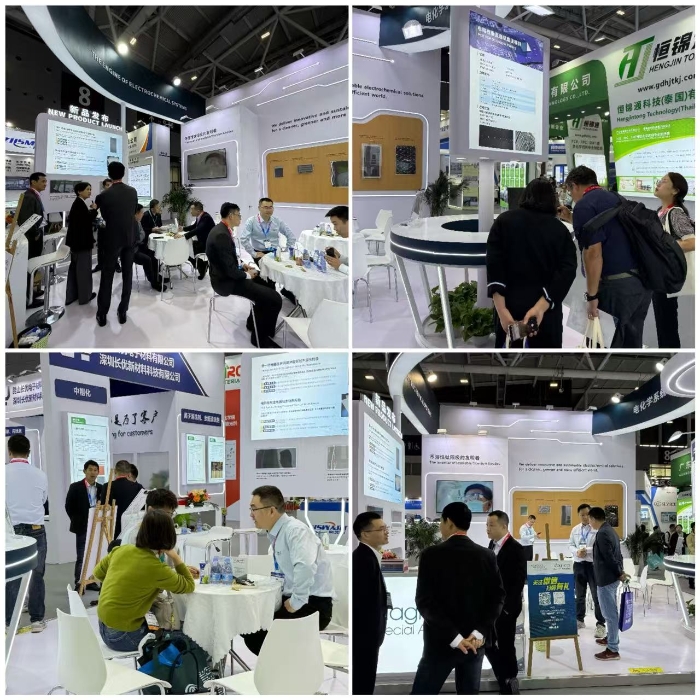

From Dec. 3 to 5, the 2025 HKPCA Show was held successfully. MAGNETO made a wonderful appearance at the exhibition, showcasing its customized high-efficiency insoluble titanium anode solutions.

Technology Sharing

Focusing on such fields as PCB electroplating, electrolytic copper foil, and general hardware electroplating, Magneto showcased a variety of high-performance titanium anode products. Relying on solid technical reserves and rich industry experience, Magneto’s professional team provided customers with professional, customized, and highly targeted anode solution support tailored to their diverse requirements in terms of application scenarios and production processes, winning high recognition and unanimous praise from visiting clients.

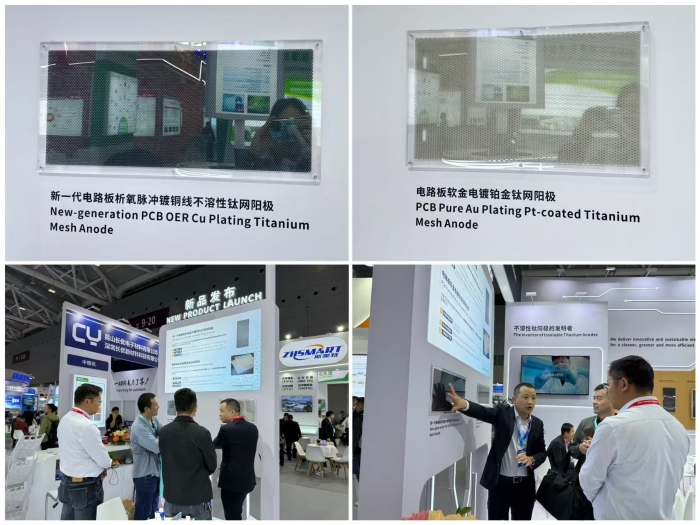

Product Innovation & Upgrades

The two innovative PCB electroplating products showcased by Magneto on this occasion are precisely tailored to the current trends of high density, miniaturization and broader application scenarios in the electronics industry, and are well-positioned to meet the advanced needs of customers in responding to the upgrading of the PCB industry.

New-generation PCB OER Cu Plating Titanium Mesh Anode (Letf Figure)

Magneto’s new-generation OER pulse anode is coated with the newly developed Selecta® MS-6 coating, custom-built for the oxygen evolution reaction pulse copper plating process.

Superior Durability: Boasts strong corrosion resistance and anti-cathodization capability, maintaining stable performance even under high-intensity pulse electrolysis conditions.

Full Compatibility: Compatible with mainstream pulse additive systems in the industry, ensuring flexibility and controllability of the electroplating process.

Outstanding Cost Advantages: Significantly extends anode service life, reduces replacement frequency and operational costs substantially, and helps customers improve economic benefits while ensuring product quality.

PCB Pure Au Plating Pt-coated Titanium Mesh Anode(Right Figure)

The newly launched platinum-titanium mesh anode by Magneto adopts an independently developed platinum electroplating process, tailor-made for high-demand soft gold electroplating processes.

Extreme Environment Resistance: Operates stably under harsh conditions such as high cyanide concentration, high temperature and high organic matter content in PCB gold plating processes, with performance far exceeding that of traditional anodes.

Greatly Extended Service Life: The new catalyst design effectively delays the failure cycle and significantly reduces replacement frequency.

Long-Term Cost Savings: Its stable and reliable electrochemical performance not only guarantees electroplating quality, but also remarkably cuts down customers’ long-term operational costs.

In-Depth Exclusive Interviews

During this exhibition, Magneto was interviewed by HKPCA's media team. From explaining why Magneto has become an important part of the industry supply chain to sharing product upgrades against the backdrop of AI development, the interview demonstrated Magneto’s strength honed by nearly 70 years of dedication to the insoluble anode industry and its continuous technological innovation that drives industry upgrading.

The 2025 HKPCA Show has concluded successfully, but Magneto’s innovation journey will never stop. We firmly believe that innovation should be rooted first in customer needs. We will join hands with customers to understand trends, adapt to trends, and lead trends, jointly addressing potential challenges with innovative strength and boosting industrial transformation. In the future, let us take new steps together to explore the new future of the PCB industry!