Although the electrolysis industry is a relatively ancient industrial field, it is rejuvenating with vitality as the popularization of new energy power generation has led to a reduction in electricity costs. Beyond traditional sectors such as chlor-alkali and electrolytic metallurgy, the electrolysis industry also plays a role in various human-related industries, including precision metal processing, precision circuit board electroplating, on-site chlorine disinfection, organic electrosynthesis, and electrolytic hydrogen production.

Electrodes are among the core components of an electrolysis system. However, the diverse range of electrochemical reactions imposes varying requirements on electrodes. In particular, the anode—prone to oxidative corrosion and dissolution—its ability to maintain stable and continuous current output is crucial for many electrolysis systems. Since the electrical industrial revolution, people have been striving to find a cost-effective anode material with dimensional stability, long service life, and corrosion resistance to drive the development of the electrochemical industry. Diverse electrolytes, demanding operating conditions, and diverse specifications of anodes have significantly increased the difficulty in anode development and manufacturing. Traditional soluble anodes, characterized by short service life and easy dissolution, fail to ensure continuous, stable, and uniform current output, making them clearly inadequate for the complex scenarios in many new electrochemical applications.

Soluble electrode | Insoluble titanium electrode |

Unstable electrode dimension | long-functional lifetime |

Frequent electrode replacement | Low maintenance requirement |

Environmentally polluting | Environmentally friendly |

Toxicity | Non-toxic |

In 1957, Dr. Henry Beer, founder of Magneto, invented the platinum-coated titanium-based electrode, which demonstrated unparalleled electrocatalytic activity and extended service life, revealing broad application prospects. Magneto thus embarked on its pioneering journey spanning nearly seven decades in the development of insoluble titanium anode technology.

Electrochemical water treatment achieves the effect of synthesizing specific water treatment agents or even directly treating specific pollutants in water through the conversion of electrical energy to chemical energy. With a short technical chain, capability for online continuous treatment, and low-carbon environmental friendliness, electrochemical water treatment technology has gradually become a priority choice among water treatment technical routes. Electrochemical water treatment places extremely high demands on the anode materials used, so the design of anode materials has become one of the core factors affecting the development of the electrochemical water treatment industry.

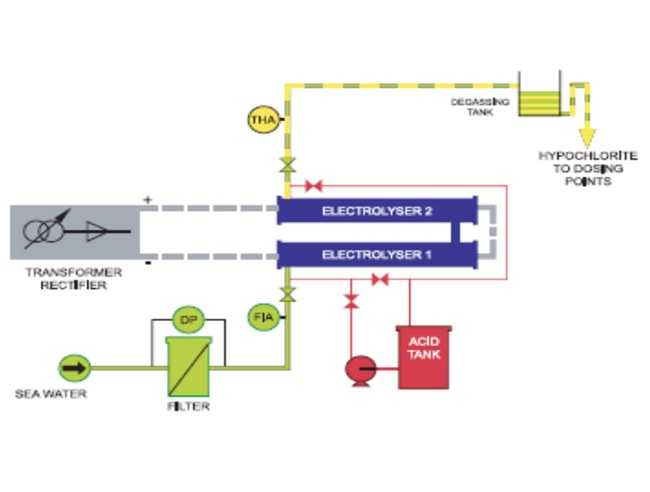

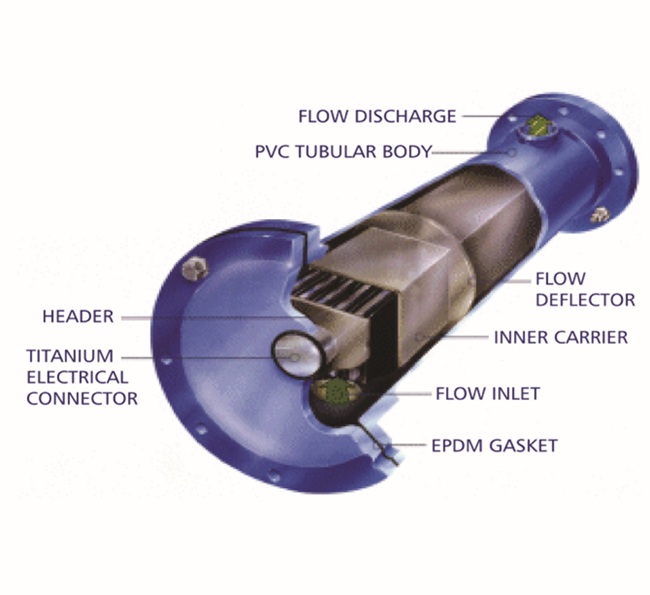

Electrochlorination Seawater,as a relatively important industry in the field of electrochemical water treatment, is primarily applied in coastal power systems. When seawater is used as cooling water, disinfection is required. Previously, most enterprises typically relied on direct dosing of finished sodium hypochlorite solutions or chlorine gas. However, over the past 20 years, driven by considerations of safe operation, Electrochlorination Seawater technology has gradually replaced the original methods of finished product dosing or chlorine gas dosing.

Electrolytic seawater technology has now reached maturity, yet several technical challenges persist that constrain its further development. Currently employed anode materials in the industry demand relatively high seawater salinity. When installed in high-salinity, high-temperature marine environments, these anodes demonstrate stable performance and satisfactory service life. However, in estuarine regions with lower and fluctuating salinity levels (such as river deltas), the electrodes are required to possess enhanced low-salinity tolerance. Failure to meet this requirement would compromise the operational lifespan of the entire Electrochlorination disinfection system.

Typical Case:A nuclear power company detected a sudden voltage rise in its Electrochlorination system. After analysis and investigation, it was found that the cause was the continuous heavy rainfall in the local area, which led to a surge in freshwater discharge from rivers into the sea. This diluted the salinity of seawater at the water intake, resulting in the failure of the entire Electrochlorination system to operate normally and irreversible damage to the electrode materials of the Electrochlorination system.

This clearly demonstrates that seawater salinity significantly affects electrode degradation rates. Electrode manufacturers must leverage their long-term technical expertise and extensive application experience to customize electrode designs according to varying water quality conditions. Improper electrode selection may compromise the stable and reliable operation of Electrochlorination system, potentially creating operational risks for power plants.

Electronic descaling for recirculating cooling water is an advanced electrochemical descaling technology for cooling water, mainly applied in industrial open recirculating water systems that use freshwater as the cooling medium. Such systems generally face issues of corrosion, scaling, and biological slime during operation. The traditional chemical agent treatment method requires large dosages of chemicals and is prone to causing secondary pollution. As a green technology, electrochemical electronic descaling has excellent industrial application value in recirculating cooling water treatment. Among them, Self-cleaning descaling technology with the ability to reverse electrode polarity is entering a stage of rapid development because it enhances the self-cleaning capability of equipment.

However, while polarity reversal technology enhances self-cleaning capability, the instantaneous switching process induces coating corrosion. At the same time, during anode cathodic treatment, hydrogenated titanium is gradually formed on the electrode surface, significantly compromises electrode stability, resulting in exponential lifespan degradation. Therefore, employing polarity-reversal-resistant specialty electrodes is critical for ensuring stable operation of reverse-polarity electronic descaling systems.

Against the backdrop of worsening environmental pollution and growing energy shortages, advanced electrolytic oxidation technology has attracted significant attention due to its highly efficient water treatment capabilities. This technology decomposes organic pollutants in water through strong oxidants generated during the electrolysis process. Meanwhile, the high oxidation potential of the electrodes can directly oxidize ammonia nitrogen into ammonia gas, thereby achieving the effects of degrading COD (Chemical Oxygen Demand) and removing ammonia nitrogen.

Although electrochemical oxidation technology has a significant effect on degrading COD and ammonia nitrogen through direct and indirect oxidation, it is limited by the complexity of wastewater components. Especially in fluoride-containing wastewater, electrodes can hardly be used. Fluoride ions have a small radius and easily react with the substrate of titanium electrodes, causing corrosion. At the same time, fluorine can also react with the catalytic coating on the electrode surface, seriously affecting the stability of the catalytic coating on the electrode surface, and the damage caused by it increases exponentially.

Therefore, it is crucial to develop suitable anodes for different water quality conditions. In-depth and detailed communication between users and electrode material developers is the key to the successful application of electrolytic oxidation wastewater treatment technology.

Magneto specializes in providing customized anode products to meet the specific application needs and technical requirements of its customers. Our professional sales, technical, R&D, and production teams work closely with clients from coating design to manufacturing, ensuring that anode solutions meet their expectations. Our flexible production capabilities and extensive experience enable Magneto to deliver high-quality, tailored solutions that help clients achieve their unique business objectives.