Amidst the global trend of the PCB industry moving towards high - end and eco - friendly development, Japan's PCB sector is strategically focusing on high - value - added areas, with semiconductors, communications, and automotive electronics being the three major application fields.

From June 4 to 6, Magneto presented its cutting - edge electrode solutions at the 2025 JPCA Show, engaging with professionals in Japan's electronic circuits industry to explore cutting - edge technologies.

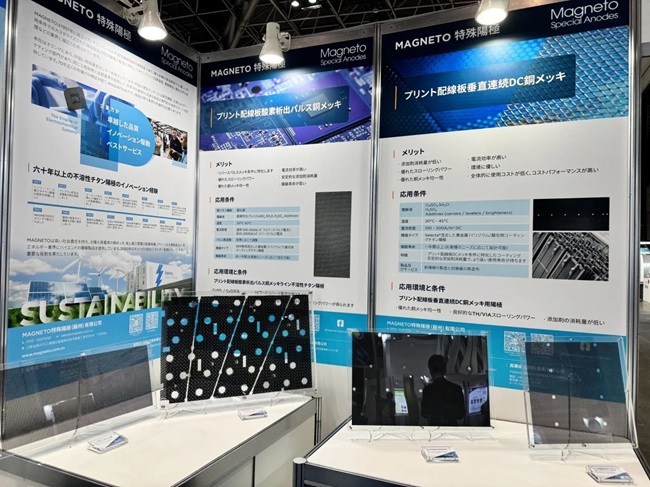

The product structure of Japan's circuit board industry is gradually shifting towards high - end products, with flexible circuits and substrates being the two main pillars. This trend imposes more stringent requirements on the precision and reliability of electroplating processes. With decades of innovative experience in insoluble titanium anode products, Magneto offers customized electrode solutions for advanced PCB manufacturing.

At this exhibition, we primarily showcased anode products applied in vertical continuous direct current copper plating lines and reverse pulse copper plating lines. By optimizing coating design, they can promote excellent throwing power and Exceptional copper thickness uniformity.

In recent years, Japanese PCB companies have been accelerating the transfer of production capacity to Southeast Asia, which accounts for about one - third of Japan's output value.

Magneto's high - efficiency, long - life anode technology can help overseas production bases reduce overall costs. Meanwhile, Magneto has an 8,000 - square - meter factory in Suzhou, covering major Asian countries and regions, enabling rapid and high - quality delivery and assisting customers in achieving a global layout.

The Japanese government has included the semiconductor/information and communications industry in the 14 key emission reduction areas in its released "2050 Carbon - neutral Green Growth Strategy."

Magneto adheres to the concept and practice of "green manufacturing" in the production of anode products, continuously optimizing water resource management, actively carrying out energy management and emission reduction work, and implementing sustainable waste management, among other environmental measures, highly matching the sustainable development strategies of Japanese clients.

Magneto’s JPCA journey has successfully concluded. Our overseas PCB footprint will continue to expand. We will see you at the THPCA Show in Hall99-100,BITEC,Bangkok, Thailand, from August 20th to 22nd!

Some content is sourced from the Global Circuit Board Industry Net Zero Carbon Emission Trends and Carbon Reduction Analysis, as well as the Global Circuit Board Industry Trend Outlook and Key Issues. If there is any infringement, please contact us for deletion.